New Oil Filtration

|

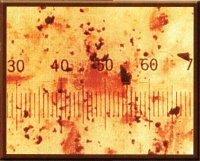

As surprising as it may seem, most new oils purchased today are not filtered before being sold. Yes, the new oil is refined, looks translucent and visually appears clean but when viewed at a microscopic level it contains unwanted particles. In many cases, the filtered oil in the equipment being replaced has less unwanted particles than the new, unfiltered oil being added during an oil change. Typically, new oils delivered to customers are rated 22/21/18 (ISO 1044c Cleanliness Standard) and sometimes worse. To eliminate the risk of adding new contaminated oil, the end user is placed in a position of having to filter new oil before it is put into service which assures:

Filtering the new oil is a very critical, proactive maintenance step. Which would you prefer, assuming or knowing that the new oil is truly clean? The oil filtration process must start with clean oil to positively impact equipment performance. With the expenses, complexities and increasing demands on equipment today one must capitalize on every performance advantage possible. New oil filtering is an easy first step to apply and a sure bet. We are ready to listen, advise, recommend a local distributor, demonstrate performance and offer a cost effective solution gained by over 40 years of industry knowledge and experience. |

||||||

|

||||||

|

|

||||||

|

|

As surprising as it may seem, most new oils purchased today are not filtered before being sold. Yes, the new oil is refined, looks translucent and visually appears clean but when viewed at a microscopic level it contains unwanted particles. In many cases, the filtered oil in the equipment being replaced has less unwanted particles than the new, unfiltered oil being added during an oil change. Typically, new oils delivered to customers are rated 22/21/18 (ISO 1044c Cleanliness Standard) and sometimes worse. To eliminate the risk of adding new contaminated oil, the end user is placed in a position of having to filter new oil before it is put into service which assures:

Filtering the new oil is a very critical, proactive maintenance step. Which would you prefer, assuming or knowing that the new oil is truly clean? The oil filtration process must start with clean oil to positively impact equipment performance. With the expenses, complexities and increasing demands on equipment today one must capitalize on every performance advantage possible. New oil filtering is an easy first step to apply and a sure bet. We are ready to listen, advise, recommend a local distributor, demonstrate performance and offer a cost effective solution gained by over 40 years of industry knowledge and experience. |

||||||||||

|

||||||||||

|

|

||||||||||

|