Oil Filter Increases Service Life

The life and health of an engine depend on the purity of the lubricants and fluids circulating inside it. Harvard filters have proven their ability to keep these fluids free of contamination, significantly extending the service life of the equipment over hundreds of applications. The life and health of an engine depend on the purity of the lubricants and fluids circulating inside it. Harvard filters have proven their ability to keep these fluids free of contamination, significantly extending the service life of the equipment over hundreds of applications.Here's a case in point: We outfitted a Caterpillar 3516 engine and compressor (right) with a Harvard oil filtration system. To establish a baseline of data for comparison, the engine was first run for 1,500 hours without a Harvard filtration system. After installation of our filters -- and another 1,500 hours of operation -- the data displayed a clear contrast. |

||||||

|

||||||

|

That's a 95.8% reduction in particles larger than 15 microns and a 99.5% reduction in particles smaller than 15 microns. This snapshot gives a clear picture fo the advantages our filtration systems can provide. But a look at the analysis of the oil over the course of the entire test brings those advantages into sharper focus. |

||||||

|

|

||||||

| Engine Oil Condition Trends | ||||||

|

||||||

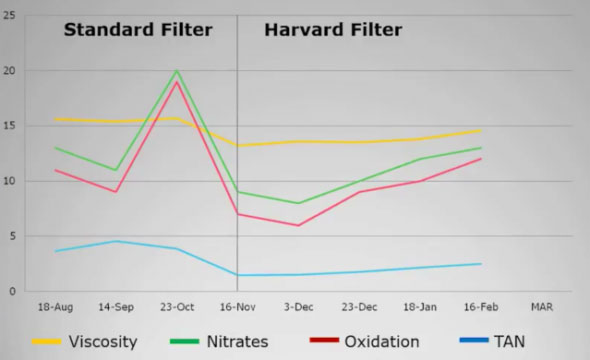

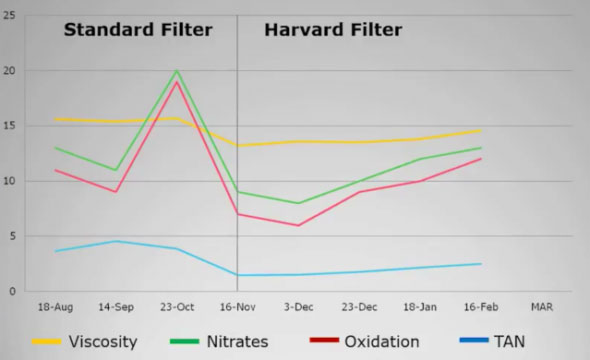

This graph displays the condition of the oil over time -- before and after the Harvard filters were installed. It shows four characteristics of the oil measured over the course of the test:

The Harvard filter's superior ability to maintain oil quality is unmistakable. Before the installation of the Harvard filters, nitrates and oxidation levels were high -- and going higher, fast. The Harvard oil filter brought those levels down and maintained the oil's viscosity and low acidity, even after 3,000 hours of operation. |

||||||

|

|

||||||

| Engine Wear Metal Trends | ||||||

|

||||||

|

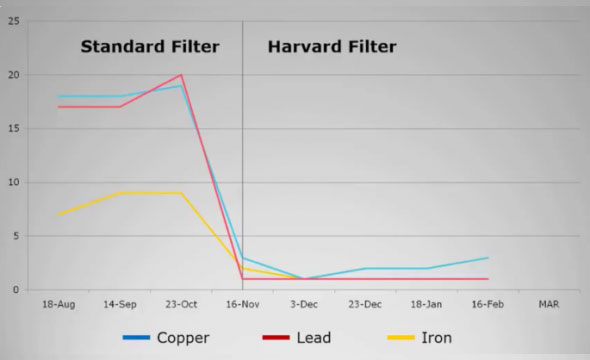

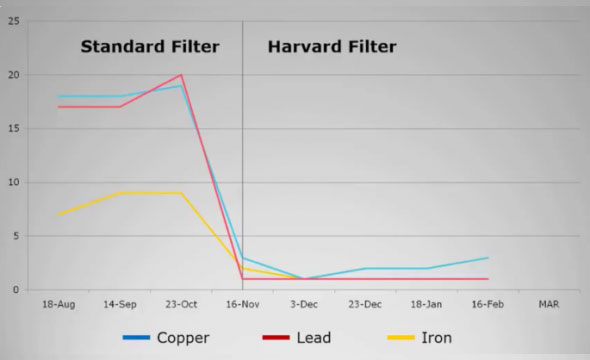

Maintaining the oil's quality had a remarkable effect on the health of the engine itself, as the measurements of engine wear metals in the graph above indicate. Before the Harvard oil filter was installed, elevated levels of copper, lead and iron were churning through the engine, wearing away at its internal surfaces. The Harvard filter reduced those wear metals by over 80%, helping to prolong the engine's service life. The effect on the engine was unmistakable. |

||||||

|

|

||||||

|

Reduced Engine Wear |

||||||

|

Though some minor carbon deposits formed on the ring grooves, the piston rings showed no evidence of rings sticking or scuffing. What's more, the piston skirt showed no signs of scuffing or excessive wear. The cylinder and bore liner showed the same absence of carbon deposits and scoring. |

||||||

|

||||||

|

Even the valve stem diameters lost just .3717" (+/- 0.0003"), on average, after 4.6 billion strokes. And the valve covers looked as good coming off the engine as they did sitting on the assembly line -- as did most of the internal parts of the engine (indicating this engine could have many more years of service life ahead of it). |

||||||

|

|

||||||

| Dramatically Extended Engine Service Life | ||||||

|

With new Harvard filters every 1,500 hours, the engine went 3,000 hours between oil changes. Where normal service life for this engine is 30,000 hours, the one with the Harvard oil filters was still going strong after 42,500 hours. We even had a Caterpillar mechanic do a "tear down" evaluation of the engine, and he said the parts didn't show the effects of over 42,500 hours of operation normally have on an engine. Increased engine life, decreased downtime, lower maintenance costs, and higher productivity -- all elements of your operation that lead to a greater return on your investments. Harvard Corporation's contamination control systems are providing these benefits to businesses throughout North and South America. |

The life and health of an engine depend on the purity of the lubricants and fluids circulating inside it. Harvard filters have proven their ability to keep these fluids free of contamination, significantly extending the service life of the equipment over hundreds of applications. The life and health of an engine depend on the purity of the lubricants and fluids circulating inside it. Harvard filters have proven their ability to keep these fluids free of contamination, significantly extending the service life of the equipment over hundreds of applications.Here's a case in point: We outfitted a Caterpillar 3516 engine and compressor (right) with a Harvard oil filtration system. To establish a baseline of data for comparison, the engine was first run for 1,500 hours without a Harvard filtration system. After installation of our filters -- and another 1,500 hours of operation -- the data displayed a clear contrast. |

||||||

|

||||||

|

That's a 95.8% reduction in particles larger than 15 microns and a 99.5% reduction in particles smaller than 15 microns. This snapshot gives a clear picture fo the advantages our filtration systems can provide. But a look at the analysis of the oil over the course of the entire test brings those advantages into sharper focus. |

||||||

|

|

||||||

| Engine Oil Condition Trends | ||||||

|

||||||

This graph displays the condition of the oil over time -- before and after the Harvard filters were installed. It shows four characteristics of the oil measured over the course of the test:

The Harvard filter's superior ability to maintain oil quality is unmistakable. Before the installation of the Harvard filters, nitrates and oxidation levels were high -- and going higher, fast. The Harvard oil filter brought those levels down and maintained the oil's viscosity and low acidity, even after 3,000 hours of operation. |

||||||

|

|

||||||

| Engine Wear Metal Trends | ||||||

|

||||||

|

Maintaining the oil's quality had a remarkable effect on the health of the engine itself, as the measurements of engine wear metals in the graph above indicate. Before the Harvard oil filter was installed, elevated levels of copper, lead and iron were churning through the engine, wearing away at its internal surfaces. The Harvard filter reduced those wear metals by over 80%, helping to prolong the engine's service life. The effect on the engine was unmistakable. |

||||||

|

|

||||||

|

Reduced Engine Wear |

||||||

|

Though some minor carbon deposits formed on the ring grooves, the piston rings showed no evidence of rings sticking or scuffing. What's more, the piston skirt showed no signs of scuffing or excessive wear. The cylinder and bore liner showed the same absence of carbon deposits and scoring. |

||||||

|

||||||

|

Even the valve stem diameters lost just .3717" (+/- 0.0003"), on average, after 4.6 billion strokes. And the valve covers looked as good coming off the engine as they did sitting on the assembly line -- as did most of the internal parts of the engine (indicating this engine could have many more years of service life ahead of it). |

||||||

|

|

||||||

| Dramatically Extended Engine Service Life | ||||||

|

With new Harvard filters every 1,500 hours, the engine went 3,000 hours between oil changes. Where normal service life for this engine is 30,000 hours, the one with the Harvard oil filters was still going strong after 42,500 hours. We even had a Caterpillar mechanic do a "tear down" evaluation of the engine, and he said the parts didn't show the effects of over 42,500 hours of operation normally have on an engine. Increased engine life, decreased downtime, lower maintenance costs, and higher productivity -- all elements of your operation that lead to a greater return on your investments. Harvard Corporation's contamination control systems are providing these benefits to businesses throughout North and South America. |