The Cost of Oil Contaminants

|

THE PROBLEM A compressor plant in the gas line of a major oil and gas provider, who is responsible for the flow of energy from the processing plant to the consumer, had a major problem with its turbines. They turned to Harvard® for help with oil contaminants. Each oil change required 1,000 liters of new oil and took two hours which meant the turbine was down for that time. The cost of these oil changes was $130,000 per year, per turbine:

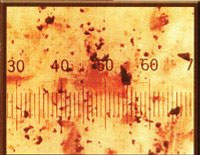

This is typical of new oil. It is processed and cleaned by the producer, but there are still contaminants in the oil. Changing the oil was not enough to keep oil contaminants under control.  THE SOLUTION THE SOLUTIONThe solution was to clean lubricating oil with a portable Harvard filtration system to ISO 16/14/10 or better. The Harvard (Model 87D) Filter system was added as a kidney loop to clean the oil as it is put into the system and while it is running. The cost of this solution is:

During the first week, the filters were changed several times. After the first week, filters were changed every six months with no downtime. THE IMPACT Oil/lubricant costs went from $130,000 per year to $632 per turbine. The cost of labor and disposal was also reduced, although no data was acquired. The oil is now changed every five years and time between maintenance of bearings and parts was extended by five times. Total savings was $125,000 per year for EACH turbine. With five turbines at the plant, total cost savings came to $625,000 per year and payback was achieved within the first month. This is typical of oil that is cleaned by the Harvard Filtration System. CONCLUSION Oil contaminants result in many direct and hidden costs which include:

Contaminants like debris and moisture are the primary cause of wear and failure. Controlling oil contaminants will save you money. Contact Harvard Corporation to see how much oil contamination control can save you. |

||||||

|

|

THE PROBLEM A compressor plant in the gas line of a major oil and gas provider, who is responsible for the flow of energy from the processing plant to the consumer, had a major problem with its turbines. They turned to Harvard® for help with oil contaminants. Each oil change required 1,000 liters of new oil and took two hours which meant the turbine was down for that time. The cost of these oil changes was $130,000 per year, per turbine:

This is typical of new oil. It is processed and cleaned by the producer, but there are still contaminants in the oil. Changing the oil was not enough to keep oil contaminants under control.  THE SOLUTION THE SOLUTIONThe solution was to clean lubricating oil with a portable Harvard filtration system to ISO 16/14/10 or better. The Harvard (Model 87D) Filter system was added as a kidney loop to clean the oil as it is put into the system and while it is running. The cost of this solution is:

During the first week, the filters were changed several times. After the first week, filters were changed every six months with no downtime. THE IMPACT Oil/lubricant costs went from $130,000 per year to $632 per turbine. The cost of labor and disposal was also reduced, although no data was acquired. The oil is now changed every five years and time between maintenance of bearings and parts was extended by five times. Total savings was $125,000 per year for EACH turbine. With five turbines at the plant, total cost savings came to $625,000 per year and payback was achieved within the first month. This is typical of oil that is cleaned by the Harvard Filtration System. CONCLUSION Oil contaminants result in many direct and hidden costs which include:

Contaminants like debris and moisture are the primary cause of wear and failure. Controlling oil contaminants will save you money. Contact Harvard Corporation to see how much oil contamination control can save you. |

||||||

|