Advantages of Filtration

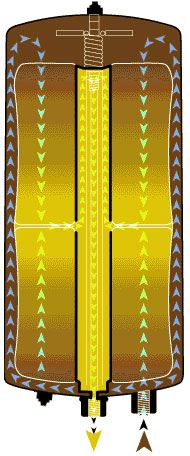

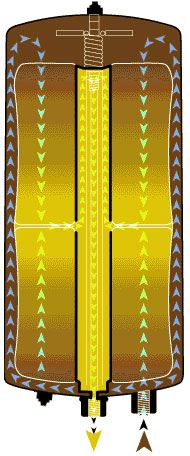

Contaminants from 1 to 40 microns in size are common even in full-flow, filtered lubricants and coolants. Larger contaminants nest into areas around bearings, rings, pumps, etc. and damage component surfaces. Smaller contaminants, that cannot be removed by full-flow filters, wear on the apparatus by a process called silting. Contaminants from 1 to 40 microns in size are common even in full-flow, filtered lubricants and coolants. Larger contaminants nest into areas around bearings, rings, pumps, etc. and damage component surfaces. Smaller contaminants, that cannot be removed by full-flow filters, wear on the apparatus by a process called silting.For many years, partial-flow filtration has been used to supplement full-flow filters to remove larger contaminants and control silting. Now, Harvard Corporation has significantly improved partial-flow filtration. Our patented, non-channeling seals improve partial-flow filtration by forcing oil through a wound, fiber-filter media so fluids cannot bypass the partial-flow filter. Independent studies conducted by the Center for Hazardous Materials Research at the University of Pittsburgh demonstrated the effectiveness of Harvard Corporation's non-channeling, partial-flow filter. According to the study our filter removes virtually all remaining 1 to 40-micron contaminants while also removing the vast majority of silting particles. In addition, the filter absorbs water, antifreeze and other extraneous particles. |

||||||

|

|

||||||

|

Contaminants from 1 to 40 microns in size are common even in full-flow, filtered lubricants and coolants. Larger contaminants nest into areas around bearings, rings, pumps, etc. and damage component surfaces. Smaller contaminants, that cannot be removed by full-flow filters, wear on the apparatus by a process called silting. Contaminants from 1 to 40 microns in size are common even in full-flow, filtered lubricants and coolants. Larger contaminants nest into areas around bearings, rings, pumps, etc. and damage component surfaces. Smaller contaminants, that cannot be removed by full-flow filters, wear on the apparatus by a process called silting.For many years, partial-flow filtration has been used to supplement full-flow filters to remove larger contaminants and control silting. Now, Harvard Corporation has significantly improved partial-flow filtration. Our patented, non-channeling seals improve partial-flow filtration by forcing oil through a wound, fiber-filter media so fluids cannot bypass the partial-flow filter. Independent studies conducted by the Center for Hazardous Materials Research at the University of Pittsburgh demonstrated the effectiveness of Harvard Corporation's non-channeling, partial-flow filter. According to the study our filter removes virtually all remaining 1 to 40-micron contaminants while also removing the vast majority of silting particles. In addition, the filter absorbs water, antifreeze and other extraneous particles. |

|||||||

|